The problem

The current market for corrugated packaging is characterised by a growing demand for a better level of service. The demand for orders with reduced volumes is increasingly common and delivery times are getting shorter. Also, there is a reduction in margins due to fierce competition between companies, so it is not surprising that production planning is increasingly complex, leading to frequent tension between the different departments involved in the flow of business activities.

Optimal organisation of the factories in this industry is therefore vital, with management and planning software available in the plant to respond to the significant challenge of reducing production costs, thereby giving improved service to the final customer.

The solution

To address this issue and achieve optimal planning, AIS has developed WinBox®.

The WinBox® system was developed in collaboration with companies in the corrugated cardboard sector.

WinBox® optimises the overall performance of the organisation:

- It serves customers better, by providing effective delivery dates allied with the capacity to react to unforeseen events.

- It results in lower production costs, and provides optimal planning based on the characteristics of the company.

- It decreases intermediate stocks due to the ‘Just in Time’ philosophy.

- It improves coordination between departments by sharing information for joint decision-making.

To achieve these objectives, the product has three major functional areas:

1. Support for compliance with realistic customer deadlines

Winbox has decision-making tools based on both current and medium term plant information: on machine loads, manufacturing alternatives, scenario simulation, etc. The aim is to acquire realistic commitments to customers, to be aware of the effects in the factory of these commitments, to make decisions to resolve imbalances and to balance the load on the machines.

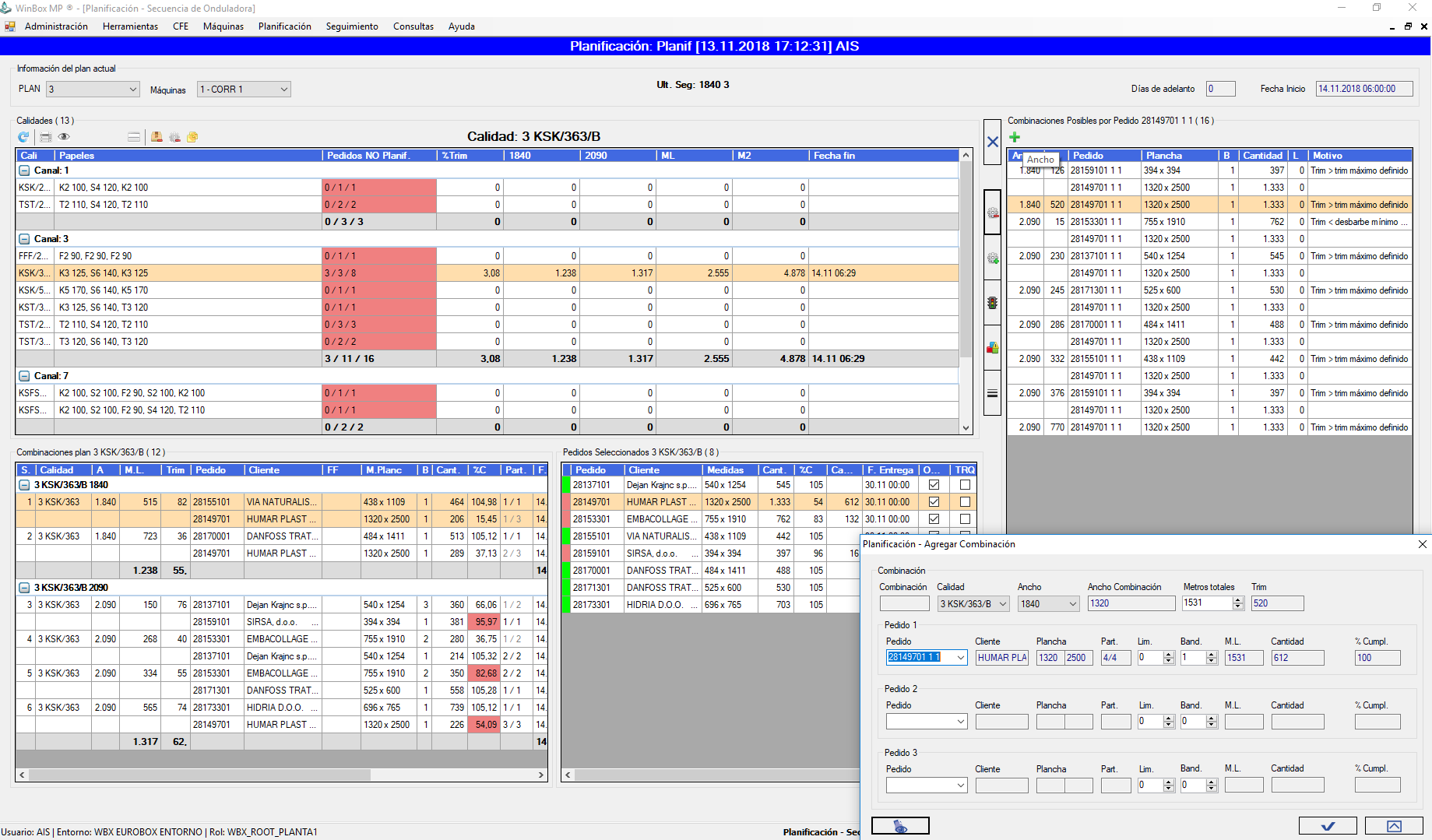

2. Optimal plant production planning

Winbox globally optimises the entire plant, while taking into account both the corrugating and processing parts.

The result is the sequence of processes that allows manufacturing with minimal waste and the maximum level of productivity, by taking into account the urgency associated with each order.

3. Production monitoring

There are a series of tools aimed at monitoring the planned production in the plant, with direct communication to the various machines, in both the corrugating and processing sections.

Learn more on Winbox with a business case.

Subscribe to our newsletter

More information on our services and solutions