The problem

The problem of cutting in a paper plant varies greatly, depending on the order volume and variability in measurements. At best, planning the cutting process is relatively simple so that an experienced person can make daily plans manually without any major complications.

The situation, however, has several drawbacks:

- Improvable costs due to the high number of possible plans. It is difficult for the experienced person to choose a plan which is the best in terms of cutting, productivity and stock.

- Under-use of time spent planning by the experienced person to perform the mechanical task of combining the production lines.

- Dependence on the experienced person. When he cannot plan well, the manufacturing plans suffer significantly.

- Inflexibility of the planning process and its effect on the level of service. Problems in incorporating last-minute changes requested by the sales department.

The solution

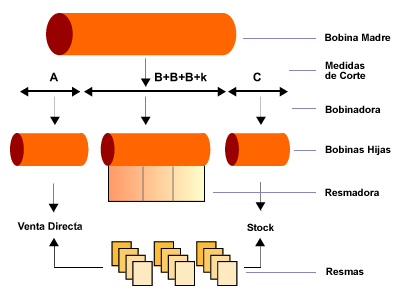

To resolve these problems, aisTrim is a software planning tool for cutting rolls of paper, whether they are cut reel to reel, from reel to a format (double cut: reel-sheet) or both at the same time, optimising the waste cost (reduction) and blade changes.

The aisTrim programme contributes to the improvement of planning in several respects:

- Reduced costs. Obtains the optimal cutting plan to minimise cutting waste, thereby maximising the productivity of the plant and adjusting the tons to manufacture to the amount of product requested by customers.

- Power to calculate. Calculates corresponding production schedules for large orders in seconds.

- Flexibility. The order book can be changed at any time and is therefore able to respond to the unexpected and a new optimal plan quickly obtained.

- Maximum added value of the experienced person in planning, as he can devote his time to considering various service scenarios.

- Scenario simulation. It can simulate various scenarios, so the most appropriate option can be chosen.

Subscribe to our newsletter

More information on our services and solutions